OLED Display

a

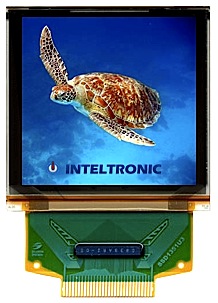

Inteltronic offers a full range of monochrome and full color OLED displays sizes from 0.66" up to 5.5".

Standard Monochrome OLED Product List

Standard Full Color OLED Product List

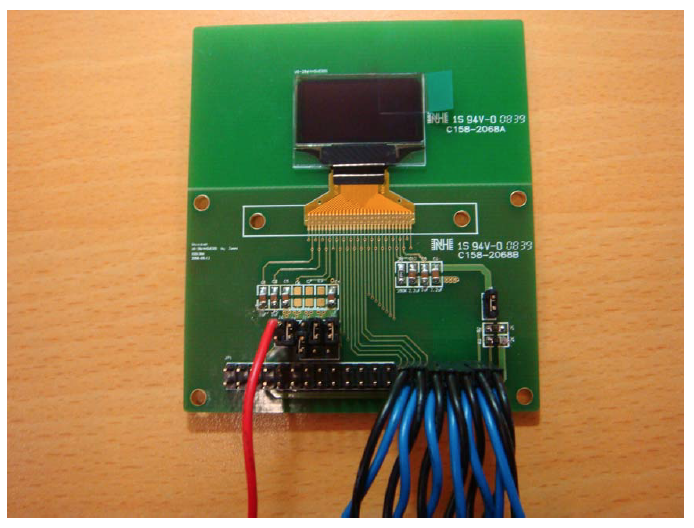

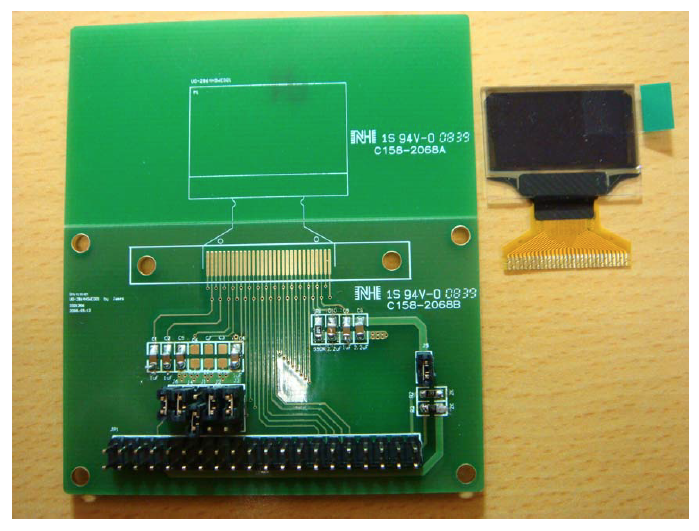

| Inteltronic OLED evaluation kit set available: Inteltronic's OLED evaluation kit set is a user friendly kit that helps you to start your chosen OLED right away. |

|||

| *The OLED display panel *Evaluation board *Use leading wire to connect EVK with your system

|

Purchase OLED sample with evaluation board Purchase OLED sample with evaluation board |

Connect to your system |

|

| Inteltronic OLED factory is ISO/TS16949 certified. | |||

Inteltronic OLEDs for your projects:a* Self-emmissive, no backlight required* Super light in weight and thin (1 ~ 2mm)*Low Power consumption: 2.8 - 3.6V

|

|

||

a

a

a

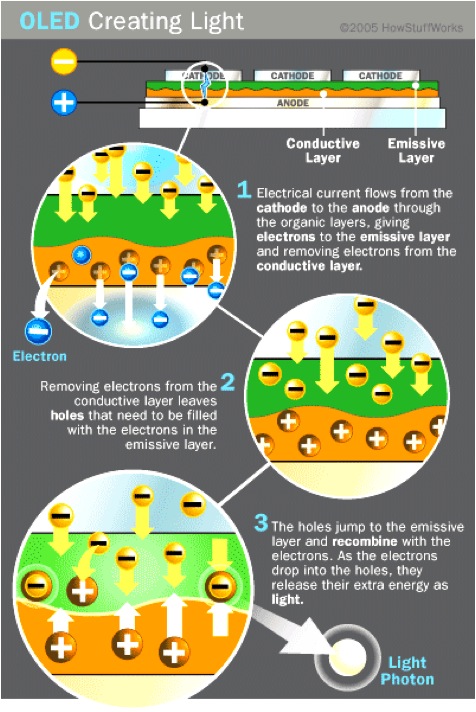

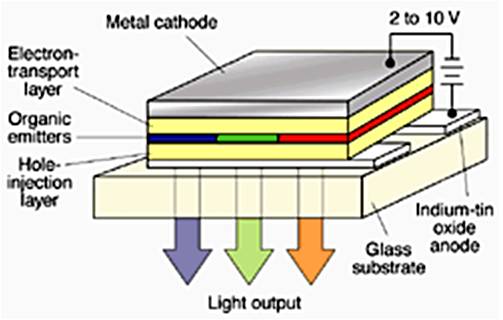

Lighting principles of OLED: What is OLED? a Organic Light-Emitting Diodes (OLED) display, also referred to as Organic Electroluminescence (OEL) display, is light-emitting diode (LED) whose emissive electroluminescent layer is composed of a film of organic compounds. There is a great scientific and commercial interest in this new OLED technology because they make color displays cheaper, sharper, thinner, and mechanically more flexible in consumer devices such as cell phones, personal digital assistants, and car dashboards. OLED technology also uses significantly less energy than current electronic displys, enabling loger battery life and increased usefulness of the products.

a

Source: howstuffworks

aa

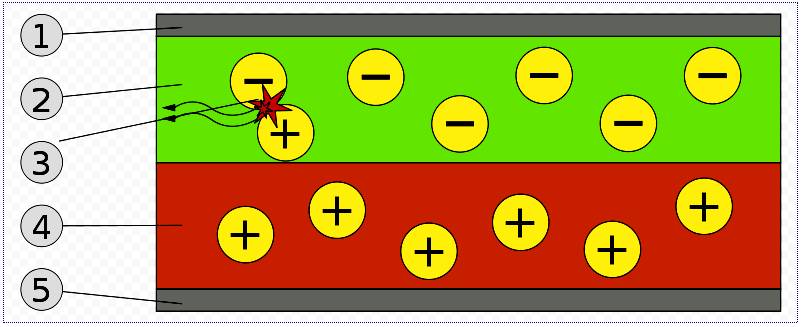

1. Cathode (−) 2. Emissive Layer 3. Emission of radiation 4. Conductive Layer 5. Anode (+)

Schematic of a bilayer OLED

Typical OLED Structure

a

Small Molecules:

a

Efficient OLEDs using small molecules were first developed by Dr. Ching W. Tang et al. at Eastman Kodak. The term OLED traditionally refers specifically to this type of device, though the term SM-OLED is also in use.

a

Molecules commonly used in OLEDs include organometallic chelates (for example Alq3, used in the organic light-emitting device reported by Tang et al.), fluorescent and phosphorescent dyes and conjugated dendrimers. A number of materials are used for their charge transport properties, for example triphenylamine and derivatives are commonly used as materials for hole transport layers. Fluorescent dyes can be chosen to obtain light emission at different wavelengths, and compounds such as perylene, rubrene and quinacridone derivatives are often used. Alq3 has been used as a green emitter, electron transport material and as a host for yellow and red emitting dyes.

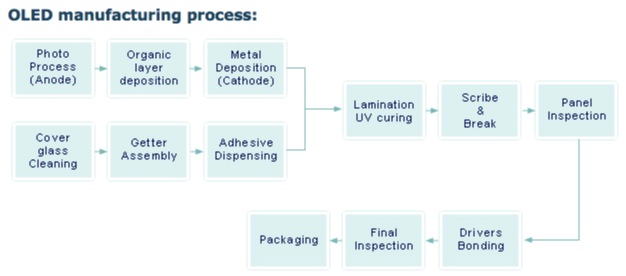

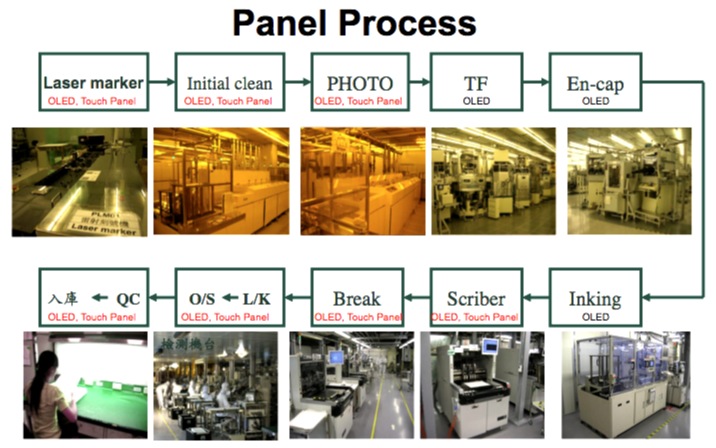

The production of small molecule devices and displays usually involves thermal evaporation in a vacuum. This makes the production process more expensive and of limited use for large-area devices than other processing techniques. However, contrary to polymer-based devices, the vacuum deposition process enables the formation of well controlled, homogeneous films, and the construction of very complex multi-layer structures. This high flexibility in layer design, enabling distinct charge transport and charge blocking layers to be formed, is the main reason for the high efficiencies of the small molecule OLEDs.

PMOLED vs AMOLED - what's the difference?

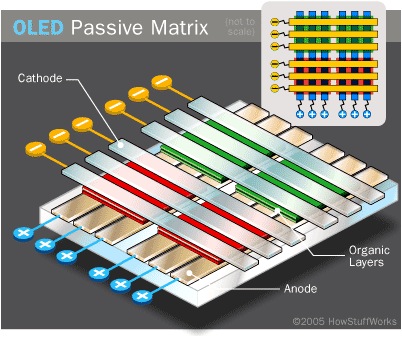

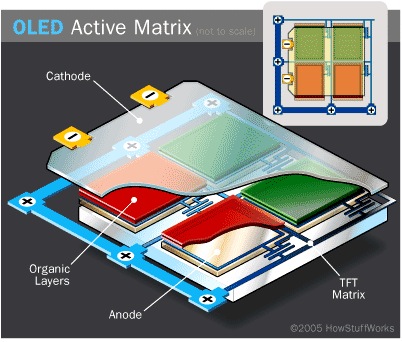

aThere are two types of OLEDs used in displays - PMOLED and AMOLED. The difference is in the driving electronics - it can be either Passive Matrix (PM) or Active Matrix (AM).

a

With Passive-Matrix OLEDs, the display is controlled by switching on rows and columns. When you turn on row number x and column number y, the pixel at the intersection is lit - and emits light. Each time you can choose just one pixel to light. So you have to turn these on and off very quickly. You do so in a certain sequence, and create the desired image. This is somewhat like the interlace-system used in old CRTs, but the control is done pixel-by-pixel. PMOLEDs are very easy and cheap to build, but they are limited to small sizes (up to 5", typically).

Source: howstuffworks

AMOLEDs have a different driver electronics - each pixel is controlled directly. AMOLEDs are more expensive, and much more difficult to create, but can be used for larger displays (current prototypes are up to 40") and are very power efficient.

a

The first OLED products in the market used PMOLEDs - these were MP3 players, sub-displays on cellphones and radio decks for automobiles. The displays were small and usually with just one or two colors. When AMOLED panels started to emerge in 2007 and 2008 we have seen these larger displays in mobile video players, digital cameras, mobile phones main displays and even OLED TVs.

a

PMOLEDs are still very popular - there are more MP3 player sold today with PMOLED than with LCDs.

a

a